Auto Parts Plastic Injection Mold/ plastic mold factory design/ moulding plastic maker

sisazhietyize

Mold Material |

Silicone |

|

Available Materials |

PU material(similar to ABS, similar to PC, similar to PP and ect.), rubber, silicone |

|

Tolerance of vacuum Casting |

+/-0.5mm or +/-0.1/30mm |

|

Cavity |

Cavity Multi or single cavity |

|

Delivery date |

Can be delivered as fast as in 7 days, but it depends on your project, usually about 20-30 days. |

Our Services |

CNC Machining Service3D Printing Service

Injection Molding Service

Vacuum casting Service

Die Casting Service

Sheet Metal Working Service |

Packaging&Transport |

Wood case or carton box,

1,With plastic bag, with pearl-cotton package.

2,To be packed in cartons or wood case.

3,Use tape to seal cartons. Or nail shut wooden crates

4,Deliver by DHL,FEDEX,UPS. Or according to customers' requirement. |

|

Payment Terms |

T/T, Credit Card, Western Union, Paypal,etc; |

-

Key Specifications/Special Features:

1. Mold-flow system is used for mold design.

2. More than 15 years in field experience in mold and part fabrication.

3. Professional sales and skillful project engineers team to ensure NPI progress well.

4. We use authorized CAD.

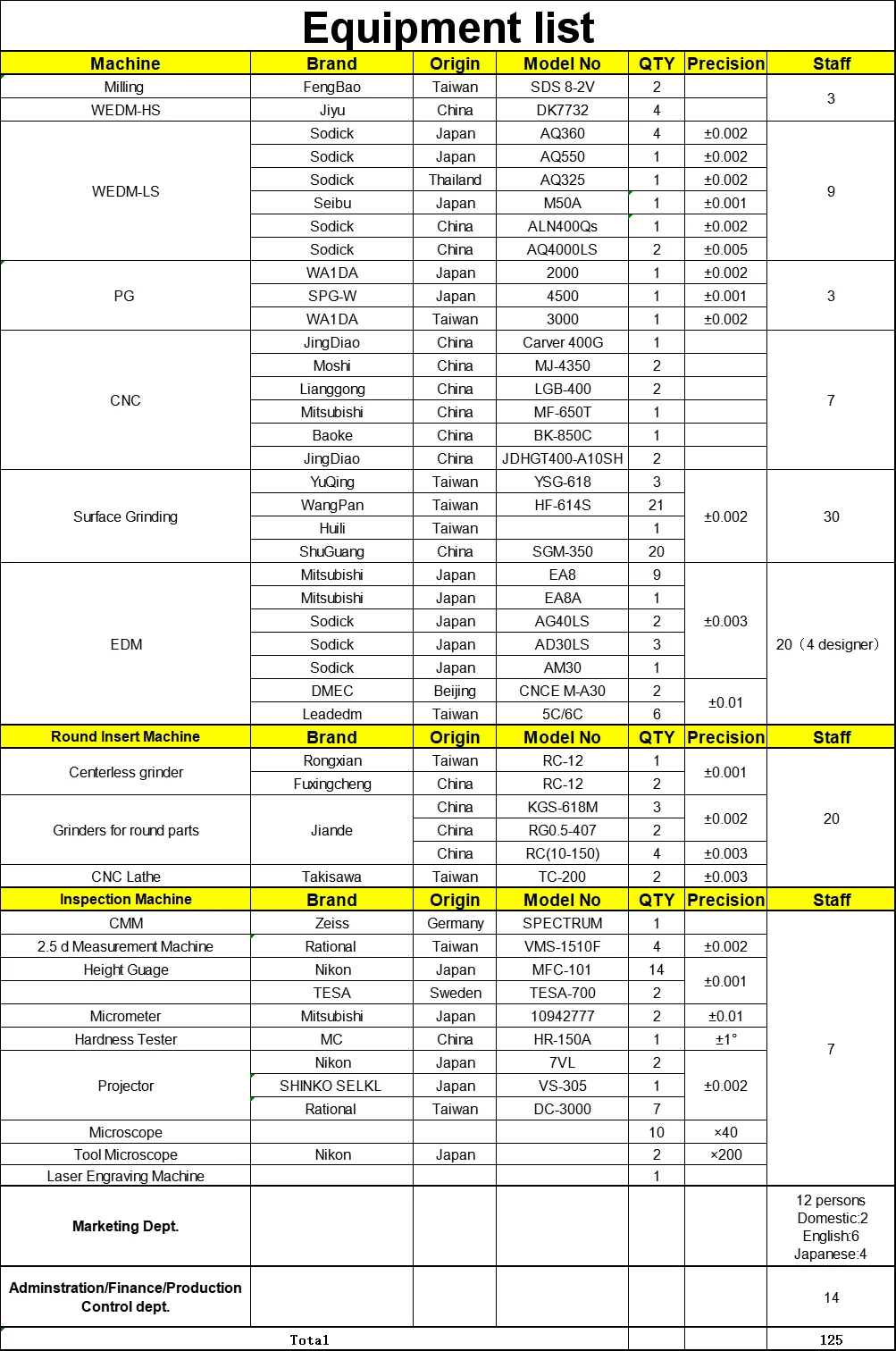

5. High accuracy Japanese machines for production.

6. QR code is used in production between different processes.

7. Small orders are accepted.

Yize company takes "Overcoming difficulties and challenging crises" as its annual business slogan, enhances the crisis awareness of all employees, calls on all employees to work together, and increases the efforts of various education and training for employees as much as possible, and pays for the unforeseen difficulties in the future. For anyones efforts.

Japan imported WAIDA profile grinding machine ensures our punch mould parts to reach the grinding precision within 0.002mm, We could also help to deal with surface treatment like TIC,TIN,TICN,TIALN if required.